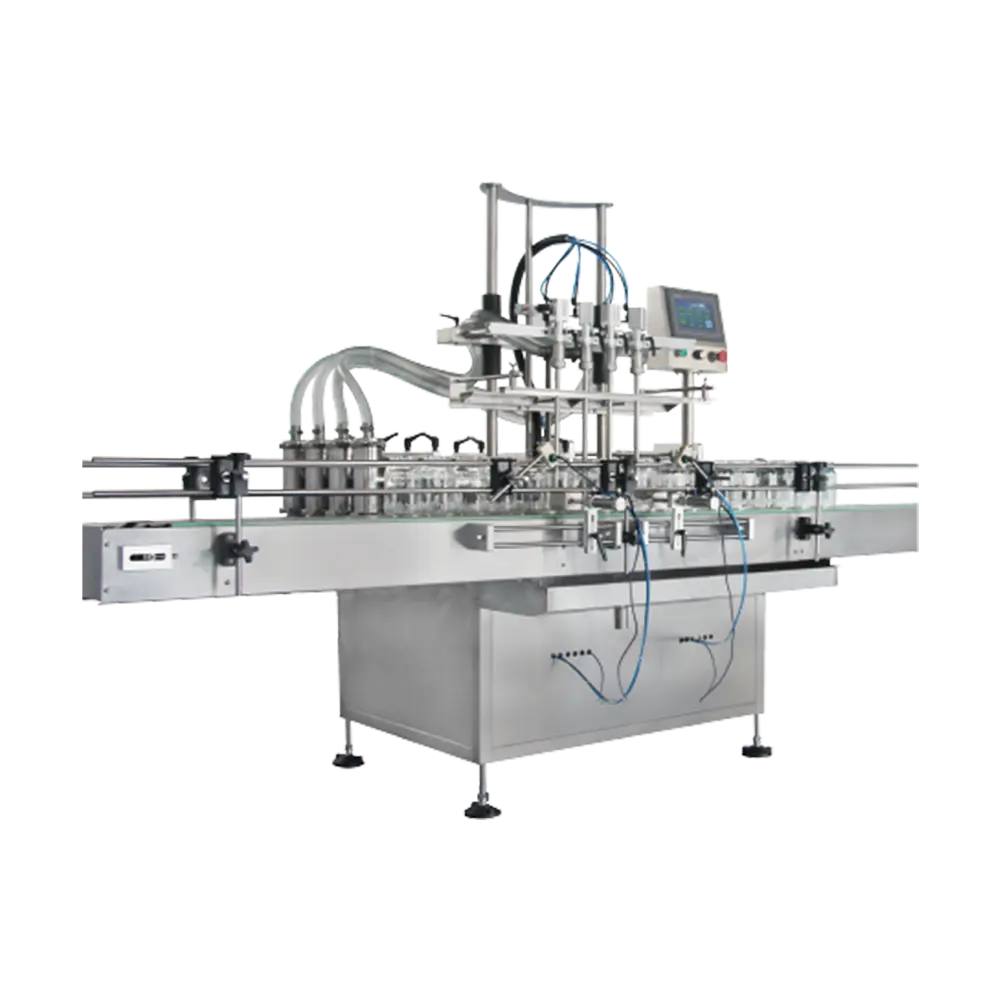

The NP-EVF stands out for its volumetric dosing capabilities, particularly with semi-viscous liquids and those exhibiting easy flow characteristics.

Key Features

- Durable Construction:Made from 304 stainless steel for longevity and hygiene, with liquid contact parts crafted from 304SS or 316SS food-grade stainless steel for enhanced safety.

- Advanced Control System: Includes a sophisticated “no bottle, no fill” system managed by PLC controls, with automatic alerts for operational failures.

- Precision Filling:Equipped with nozzles that prevent drips and silk, cutting off viscous liquids automatically for clean and accurate fills. The filling volume accuracy is within ±0.5%, supported by a comprehensive bottle counter.

- Easy Maintenance:The horizontal piston-cylinder design simplifies disassembly and cleaning, with no specialized tools required.

- Corrosion Resistance:Uses special SKF seals or hoses for handling corrosive liquids.

- Versatility:Offers diving nozzles for bottom-up filling of foaming products, ensuring a wide range of applications. The machine is also capable of accurately locating the bottle mouth for precise filling, while standard drip trays are included to enhance overall cleanliness and efficiency during the filling process.

Application Industry

Moreover, in practical applications, the NP-EVF has demonstrated excellent stability and reliability. Whether handling different types, concentrations, or temperature ranges of liquid substances, this equipment consistently performs tasks with robustness, all while maintaining low maintenance costs and long service life. This reliability has made the NP-EVF widely used on production lines, earning unanimous praise from users.

In addition, the NP-EVF is also noteworthy in terms of environmental protection. It employs advanced technology to minimize waste production and resource consumption during operation, meeting the growing demand for green and environmentally friendly production methods in today’s society.

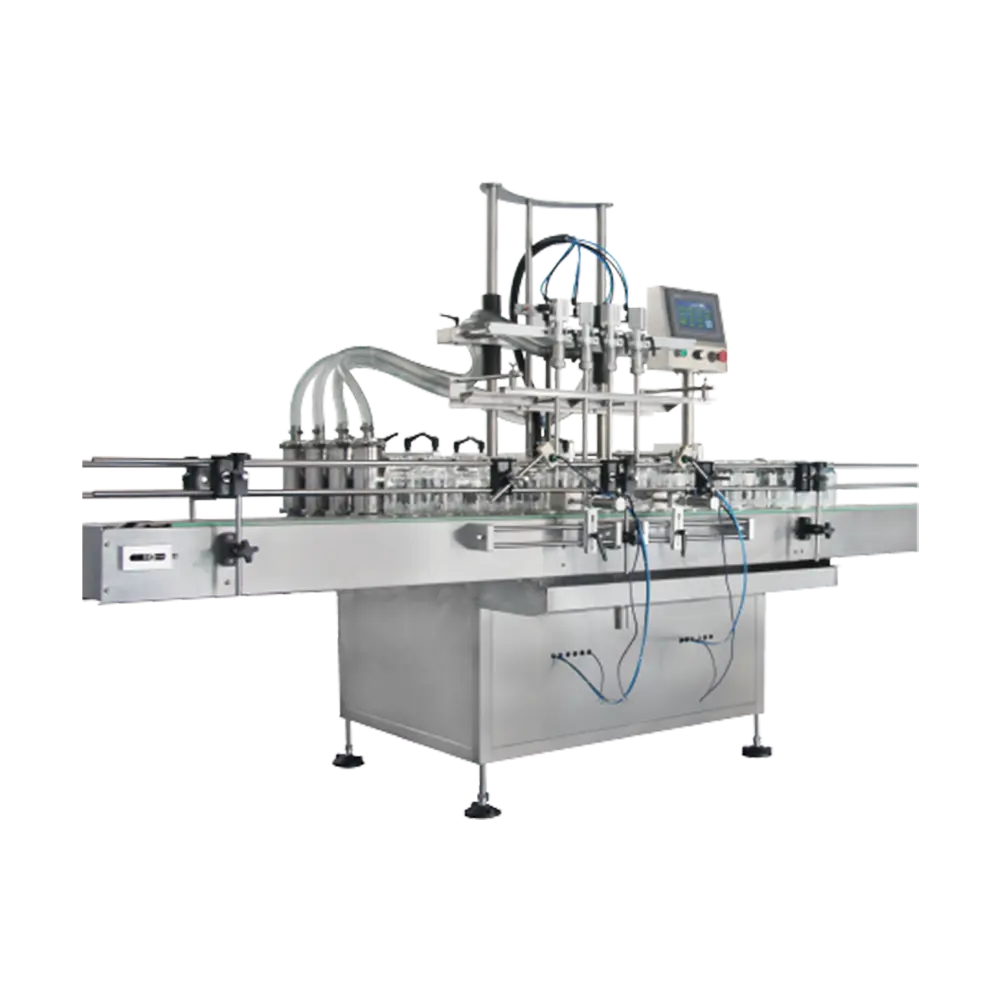

Technical Parameters

| 1 | Model | NP-EVF |

| 2 | Operational mode | Automatic |

| 3 | Product applications | For liquid and viscous liquid |

| 4 | Filling range | 100-1000ml or 500ml to 5000ml |

| 5 | Number of heads | 2 or 4 heads |

| 6 | Filling Capacity | 500b/h to 1200b/h base on 1000Ml viscous liquid |

| 7 | Measurement precision | ±0.5% base on 1000ml |

| 8 | Working power | 220VAC single phase |

| 9 | Air pressure | 6~8㎏/㎝² |

| 10 | Air consumption | 1m³/min |

| 11 | Power rate | 0.8kw to 1.5KW |

| 12 | Other devices power rate | 7.5kw(air compressor) |

| 13 | Net weight | 320Kg |

Option Features

This equipment features advanced technology and design with a variety of functional features:

– It is equipped with vacuum filling nozzles, which can effectively maintain the freshness and quality of the product.

– Pressure top tank, focusing on pressure control.

– Rotary valve for granular solid food paste optimizes material flow.

– A servo motor drives the filling nozzle up and down, ensuring precision and stability of operation.

– Each stroke of the piston drives each servo motor independently, making the operation more flexible and controllable.

– The specially designed closed filling nozzle not only improves production efficiency but also effectively prevents corrosion of liquid products on the machine.

– To meet different needs, the design takes into account the use of PTFE pumps, PTFE hoses, and seal materials, and optimizes for high-corrosive liquid products.

– The mixing top hopper and double-layer jacketed hopper with heating function further enhance the device’s suitability and convenience for handling various materials.