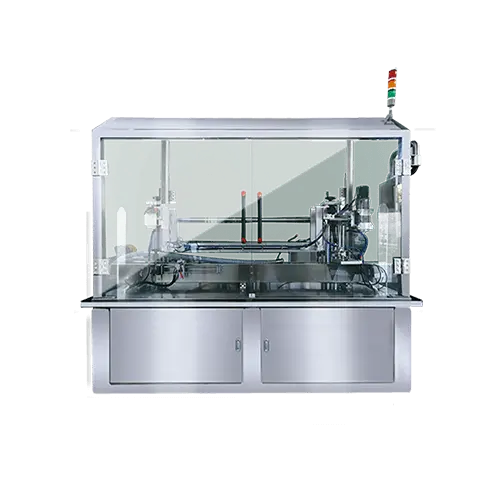

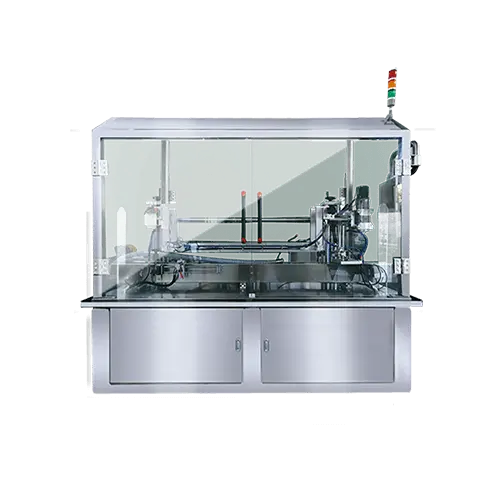

It utilizes advanced ionized air rinsing technology to ensure that bottles, glassware, and various containers are rinsed, enhancing hygiene standards.

Key Features

Robust Material: The main components of our automatic high-speed bottle washing machine are constructed using 304/316 stainless steel material. Not only does this ensure a visually appealing appearance but also provides strong corrosion resistance, stable performance, and low maintenance costs over time.

User-Friendly Interface: Equipped with intuitive interfaces that allow easy adjustment of settings, real-time monitoring of the cleaning process, and troubleshooting capabilities if needed; our ionized air bottle rinsers provide convenience for operators while maintaining optimal performance standards.

Technology: The machine can effectively remove and neutralize particles adhering to the bottle’s surface. By utilizing ionized air rinser technology, our machine can efficiently clean dust, debris, and contaminants from bottle surfaces, thereby enhancing product quality and safety.

Washing Speed: Our machine can wash bottles fast and thoroughly and is suited for continuously flowing bottles on high-speed packing production lines. It can handle abundant bottles in a short time while not affecting the cleanliness.

Low Consumption: In comparison to traditional water-based flushing methods, the ion air flushing system significantly reduces water consumption. This manner promotes sustainability and reduces operational costs for businesses.

Range Applicability: This machine can handle different bottle sizes and shapes while effectively cleaning and disinfecting various containers. Its versatility makes it an ideal solution for businesses with diverse packaging needs.

Integrated Production Line: When paired with complementary equipment such as glass or plastic bottle filling machines, capping machines, and labeling machines, our ionized air bottle rinser seamlessly integrates into liquid production lines. This integration enhances overall production efficiency by streamlining the bottling process.

Application Industry

The Ionized Air Bottle Rinser, developed and produced by NPACK, is a cutting-edge solution to address the issue of bottles not being thoroughly cleaned. This innovative machine utilizes advanced technology to ensure that bottles, glassware, and various containers are impeccably rinsed, promoting enhanced hygiene standards. One of the key features of this system is its linear conveyor belt transmission design. By employing this mechanism, the Ionized Air Bottle Rinser optimizes efficiency and accuracy in the cleaning process. Here are some relevant application industries.

- Food and Beverage Industry

Bottled Water Production: Ensures that water bottles have no pollution before filling.

Soft Drinks and Juices: Used to clean bottles before filling them.

Breweries: Removing any particles that may have accumulated during the storage or transport of empty bottles.

Dairy Products: Rinsing bottles are used for milk and other dairy products to ensure that they are free from contaminants.

- Pharmaceutical Industry

Medicine Bottling: Ensures that containers used for syrups, liquid medications, and other pharmaceutical products are sterile and free from particles.

Nutraceuticals: Applied in the preparation of bottles for vitamins, supplements, and other nutraceutical products.

- Cosmetics and Personal Care

Skin Care Products: Used in the preparation of containers for lotions, creams, and other skincare products, ensuring they are free from pollution.

Hair Care: Ensures that shampoo, conditioner, and other hair care product bottles are clean before filling.

Technical Parameters

| Power | 220V 1Phase, 0.75KW |

| Applied Container | Plastic Bottles, Glass Bottles, Jars |

| Speed | 20-60b/m |

| Rinsing Heads | 4,6,8,10 12 and 16 heads |

| Air Pressure | 0.6MPA |