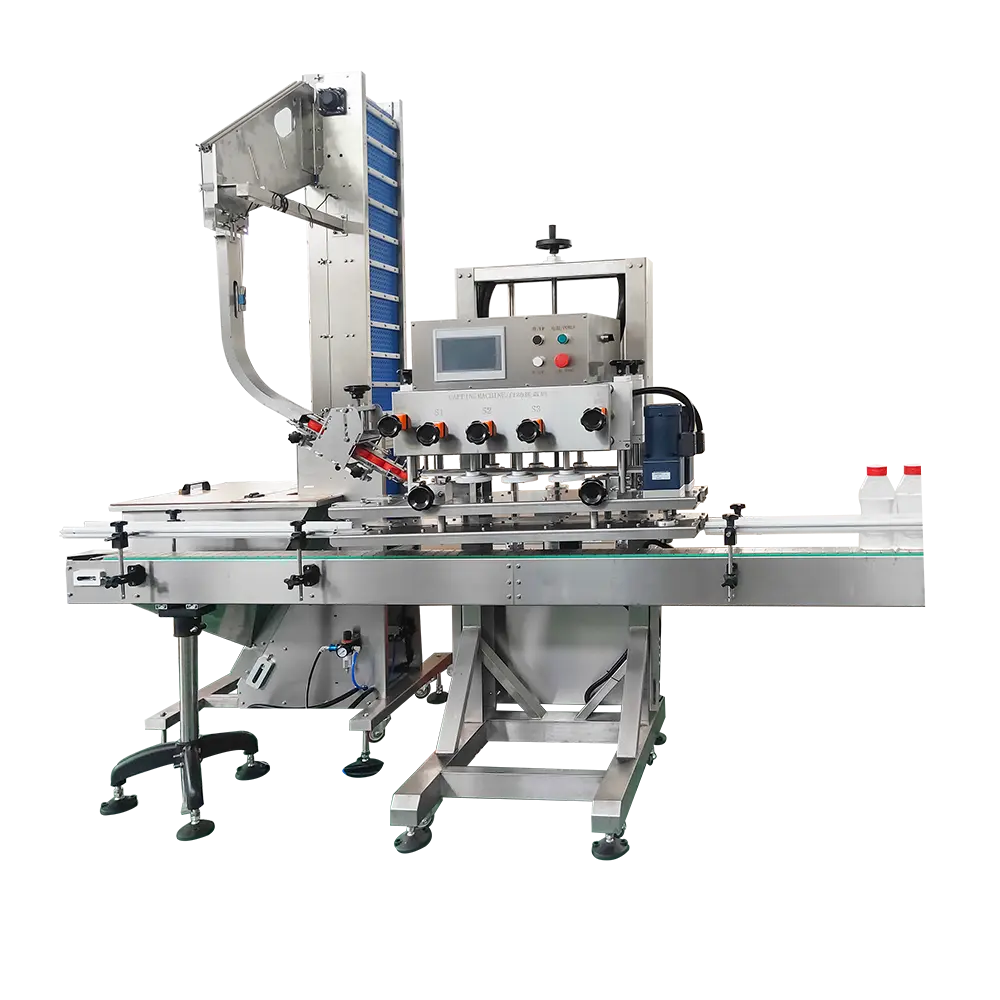

Spindle cappers can tighten and torque most types of threaded caps onto most kinds of bottles, and the caps can range in size from 8 mm to 110 mm.

Key Features

– The machine’s six main spindle wheels not only ensure consistency and accuracy in cap application but also efficiently seal and maintain the integrity of various products. This feature is particularly suitable for industries requiring precise packaging, such as pharmaceutical or food production.

– The machine is equipped with two sets of mechanical clutches, which provide excellent control over torque application during the capping process. This ensures that each cap is precisely and securely tightened without compromising the integrity of the cap or the product inside. For users seeking higher performance and ease of operation, a servo motor drive system is available as an optional feature.

– The setup process for this machine is made simple through easy-to-use front knob adjustments. These adjustments allow for quick and accurate changes to accommodate different cap sizes and types, making it effortless to transition between different products on a production line.

– To enhance operational efficiency and reduce noise levels, this machine features a sophisticated non-vibratory feeder system. This system provides a steady supply of caps to the capping mechanism while minimizing disruptions caused by vibrations. Additionally, depending on cap size, the feeder has a capacity to store up to 800pcs at one time (depending on different sizes).

– Offering exceptional flexibility in packaging needs, this machine is capable of handling caps ranging from 8 mm to 120 mm in size. It can accommodate various types including 400 caps (commonly used for beverages), 410 caps (often found in cosmetics), as well as CRC caps (child-resistant closures) commonly used in pharmaceuticals.

– Designed for fast and easy changeovers between different products or packaging requirements, this machine significantly reduces downtime during production processes. By streamlining changeover procedures, more time can be dedicated to actual manufacturing activities.

Key Features

| NAME MODEL | NP-LC Automatic linear spindle capping machine |

| Capacity | 0~200b/m(subject to bottles and cap size) |

| Bottle and cap diameter | Φ10~120 subject to samples |

| Bottle Height | 40~380mm |

| Spindle capping machine dimension | L1060*W896*H1620mm |

| Voltage | AC 220V 50Hz |

| Power | 1600W |

| Weight | 500kg |

| Cap Feed system | Elevator feeder |

| Dimension | L880×W1000×H2600mm |