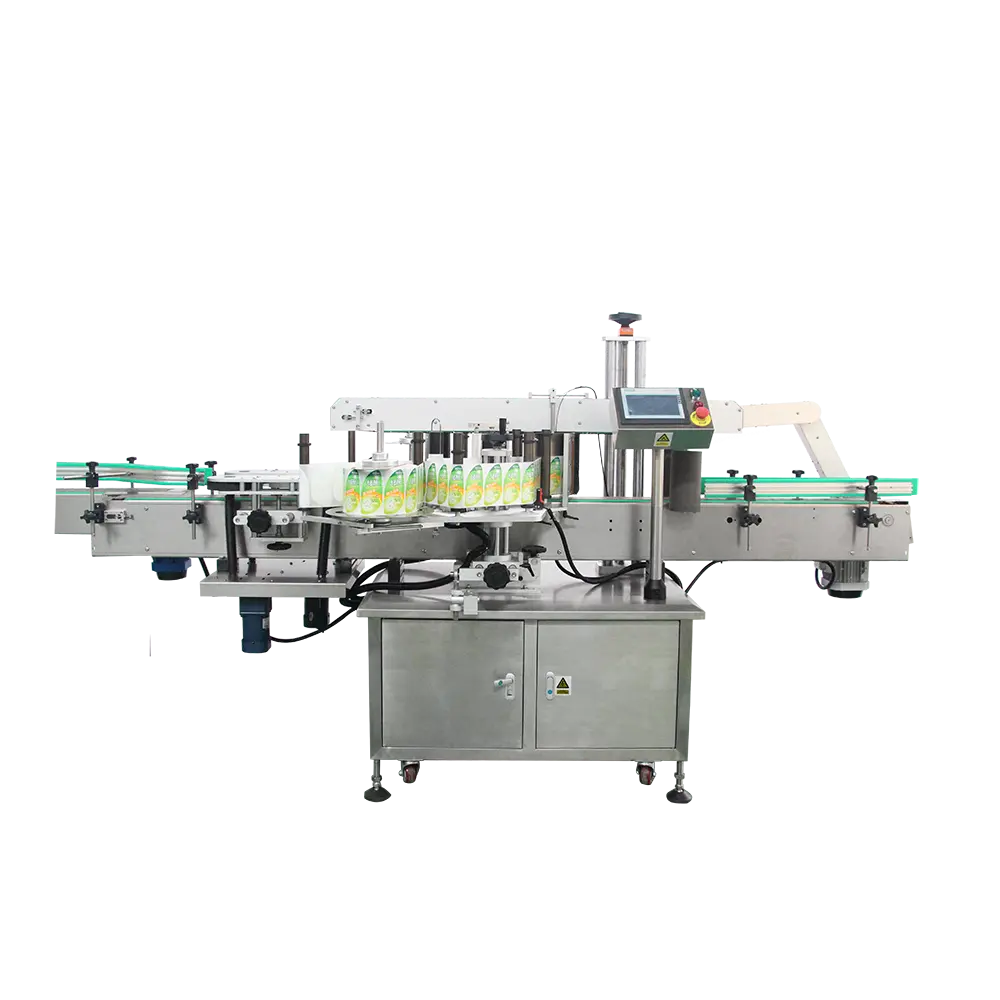

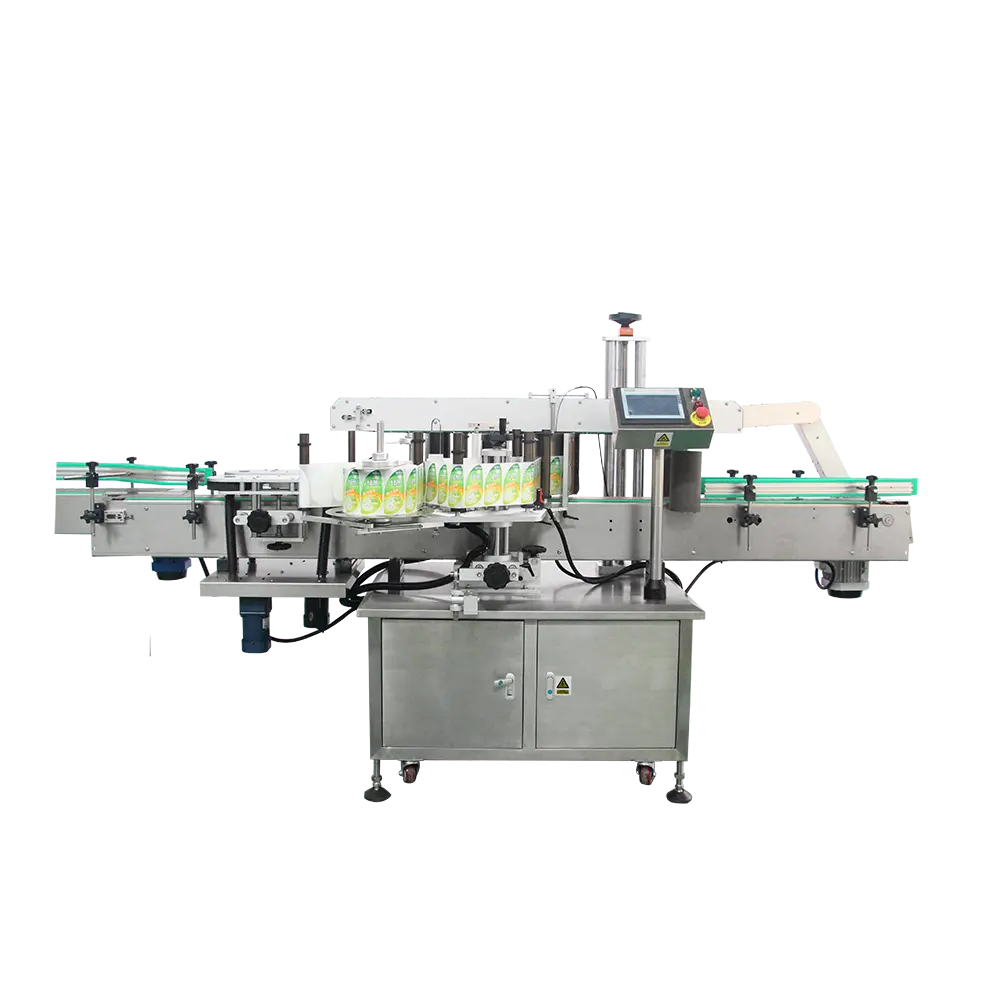

Automatic, self-adhesive labeler that excels in double-sided and single-sided sticker labeling, suitable for flat, square, and round bottle shapes.

Key Features

-Made of 304/316-grade stainless steel, it is constructed and resistant to corrosion, rust and chemical damage and suited for different applications and industries. Not only does it meet GMP standards, it also ensures its durability and complies with health and safety regulations.

-The adjustable labeling height ensures that labels are accurately applied to containers of varying sizes.

-Our advanced control system is equipped with the most advanced color Siemens smart HMI, which provides stable control and operation capabilities, ensuring efficient monitoring of various processes.

-Chinese and English bilingual operation interface, which allows users from different language backgrounds to easily operate the system without encountering any language barriers.

-With the help of an automatic bottle separation mechanism, these labeling heads can effectively separate bottles from each other to prevent any potential jamming or overlapping issues during labeling.

-The correction mechanism built into the Panasonic servo motor-driven labeling heads detects any misalignment or deviation in real-time and makes the necessary adjustments to ensure that the label is consistently and accurately applied to each bottle.

-Powered by a highly efficient and precise servo motor, the labeling machine is seamlessly integrated with a state-of-the-art programmable logic controller (PLC), ensuring not only unparalleled accuracy but also exceptional stability, reliability, and efficiency.

Option Features

Ribbon Coding Machine: It can print production date and batch number, which can improve the efficiency and accuracy of product labeling.

Industrial Zebra Engine: Transcoding printing, which can seamlessly convert and print various file formats. It is also good at docking with system software. This function can be seamlessly integrated with the labeling machine, and enterprises can achieve on-demand label production without any delays or interruptions.

Detection of labels with transparency: Suitable for all types of labels, such as gilded, transparent, paper-based, or composite S material labels. No sensor replacement is required when switching between different label types. Detection specifically focuses on the lower lining of transparent labels.

Visual inspection removal: It is capable of identifying the absence or presence of the label, as well as verifying the accuracy of printed information such as batch number and content.

Heat transfer intelligent coding machine: This device is capable of imprinting label paper with QR codes, barcodes, production dates, batch numbers, and other printing features. Furthermore, it enables product traceability while effectively combating counterfeiting activities.

Parameters

| Technical Parameters | |

| Labeling Speed | 60-350pcs/min (Depending on label length and bottle thickness) |

| Height of Object | 30-350mm |

| Thickness of Object | 20-120mm |

| Height of Label | 15-140mm |

| Length of Label | 25-300mm |

| Label Roller Inside Diameter | 76mm |

| Label Roller Outside Diameter | 420mm |

| Accuracy of Labeling | ±1mm |

| Power Supply | 220V 50/60HZ 3.5KW Single-phase |

| Gas Consumption of Printer | 5Kg/cm^2 |

| Size of Labeling Machine | 2800(L)×1650(W)×1500(H)mm |

| Weight of Labeling Machine | 450Kg |